INDUSTRIAL COMPANIES

Central administration with one system

pitFM Maintenance Management offers an integrated system for forward-looking planning and legally compliant implementation of your maintenance measures. Maintenance cycles, inspection dates and fault reports are managed centrally and collaboration with internal teams and service providers is efficiently supported.

RFID or barcode systems enable fast mobile identification of systems directly in the production environment. This allows maintenance logs, test reports or external services to be recorded and documented directly on site (even offline).

Safety-relevant systems such as pressure vessels or electrical operating systems can be recorded, classified and linked to inspection obligations. This allows you to keep an eye on all operator responsibilities, reduce and assess risks and create the basis for smooth, safe operation.

Clear structures

pitFM Area Management allows you to record and analyze operating areas. Production lines, logistics areas, technical ancillary rooms or office areas can be clearly delineated and digitally visualized with the pitFM Viewer. Optionally, pitCAD is also available for linking with CAD/BIM data. Linking with operating resources, cost centers or users creates a complete picture of the use and occupancy of all areas. Changes to the layout or occupancy status can be documented and tracked at any time.

Safety-relevant aspects

pitFM Safety and Occupational Health offers a comprehensive tool for managing and documenting all safety-relevant aspects such as risk assessments, instructions, training and accident reports through to the identification of hazardous substances and coordination of the use of PPE (personal protective equipment). All measures and evidence can be centrally documented, regularly checked and retrieved in accordance with audit requirements. Relevant information from inspections, test reports, defects and measures are recorded centrally and documented in a traceable manner. Industrial companies can use this module not only to ensure their legal compliance, but also to actively promote the health and safety of their employees.

Further process modules

Our solutions

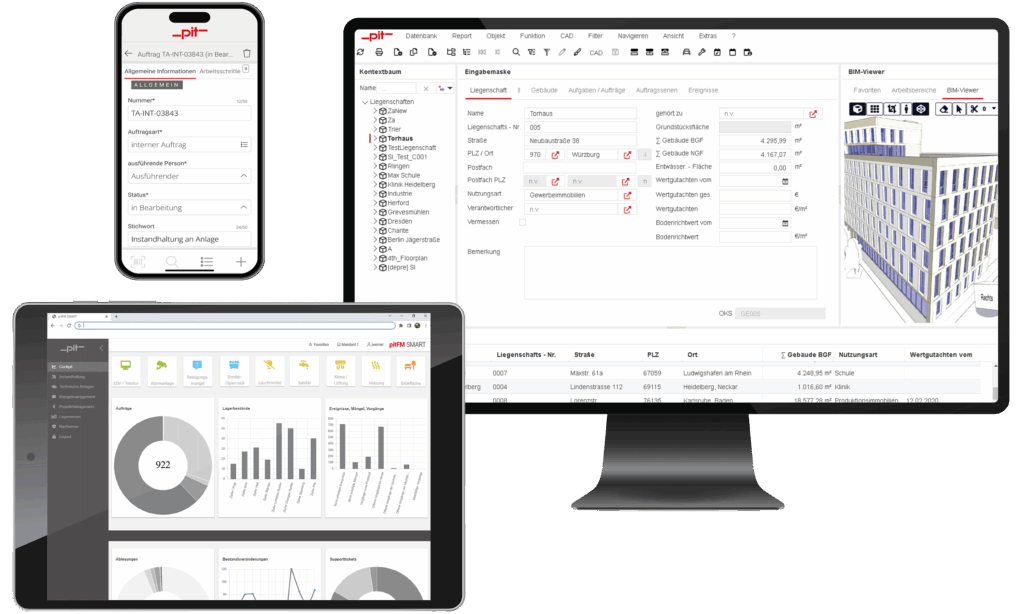

pitFM

Digital control center for building management

pitFM provides you with an end-to-end solution for intelligent, digital facility management. The software adapts precisely to your role, your tasks and your requirements. With three interfaces pitFM Expert, pitFM Smart and pitFM 2GO and a common data model, pitFM ensures maximum efficiency, transparency and usability.

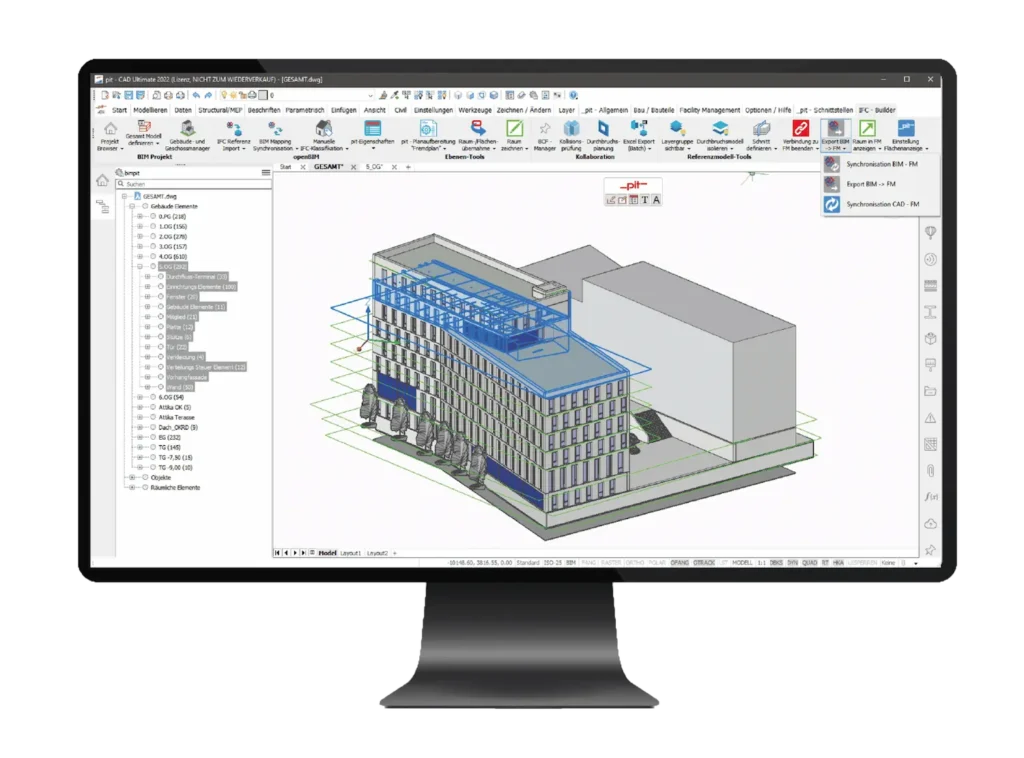

pitCAD

From planning to ongoing operation

With pitCAD Ultimate you can rely on powerful CAD/BIM software that specifically takes into account the requirements of building operations. Whether for space management, maintenance or documentation, our software solution ensures seamless operation. The software combines over 30 years of CAD expertise with the latest openBIM technology. In a familiar DWG environment, you can model 2D/3D plans, integrate IFC models and link your planning directly to building operations. Without an additional CAD basis, completely modular and seamlessly integrated into the pitEcoSystem+ for planning, construction and operation.

pitENERGY

Energy flows in real time

Keep an eye on your energy flows in real time. pitENERGY automatically monitors consumption, recognizes patterns with the help of AI and takes into account influencing variables such as weekdays, vacations or the current outside temperature. With over 200 interfaces to meters, sensors, smart metering and interfaces such as REST-API, BACnet etc., pitEnergy is the ideal supplement during operation to identify potential savings and achieve sustainability goals. In addition, pitEnergy supports you in meeting legal requirements such as the GEG (Building Energy Act).